Technological equipment for business

Telesicurezza Service's structure and ability to manage increasingly significant orders has enabled our company to stand out for its quality and respect for deadlines, carrying out projects in fields such as: Electrical systems, switchboards, MV and LV cabins, air conditioning, air treatment, water systems, heating, lighting, home automation, networks and structured cabling, electrical and electronic automations for the banking, hotel, port, industrial, museum and archaeological sectors. Work of great value and size has also been carried out for theme parks and numerous shopping centres, becoming a reference point in the engineering sector. In order to support customers in the correct management of their assets and respond promptly to any request when necessary, the maintenance division was created with specific skills in the various sectors and the ability to fulfil Global Service contracts. Great attention is paid to the energy efficiency division which channels the company's experience in the plant engineering and renewable sectors for the analysis and implementation of upgrades and energy saving alterations.

Thanks to the expertise it has acquired through responding to customers' needs, the company operates throughout Italy and also develops projects in Middle Eastern countries, guaranteeing quality and professionalism for anyone looking for a company with solid experience that looks to the future and innovates.

Electrical and home automation systems

INDUSTRIAL ELECTRICAL INSTALLATIONS: HOW TO DESIGN AND IMPLEMENT THEM SAFELY

Carrying out an industrial electrical installation is more complex than a civil electrical installation.

This is due both to the presence of more complex machinery and to the strict regulations on the subject. For this reason, it must be designed and carried out by experienced and qualified personnel.

FM distribution systems

Downstream of the secondary distribution panels is the actual energy distribution network which is designed to serve all motive power, lighting, service sockets and all the equipment that services user systems.

This distribution follows the architectural development of our customers' facilities and is essentially conveyed through steel ducts and walkways designed to contain and mechanically protect the distribution lines; it then continues in the detail of the last few metres with steel piping until it reaches the final user.

Electricity distribution is carried out according to the specific needs of each customer, always considering basic design criteria.

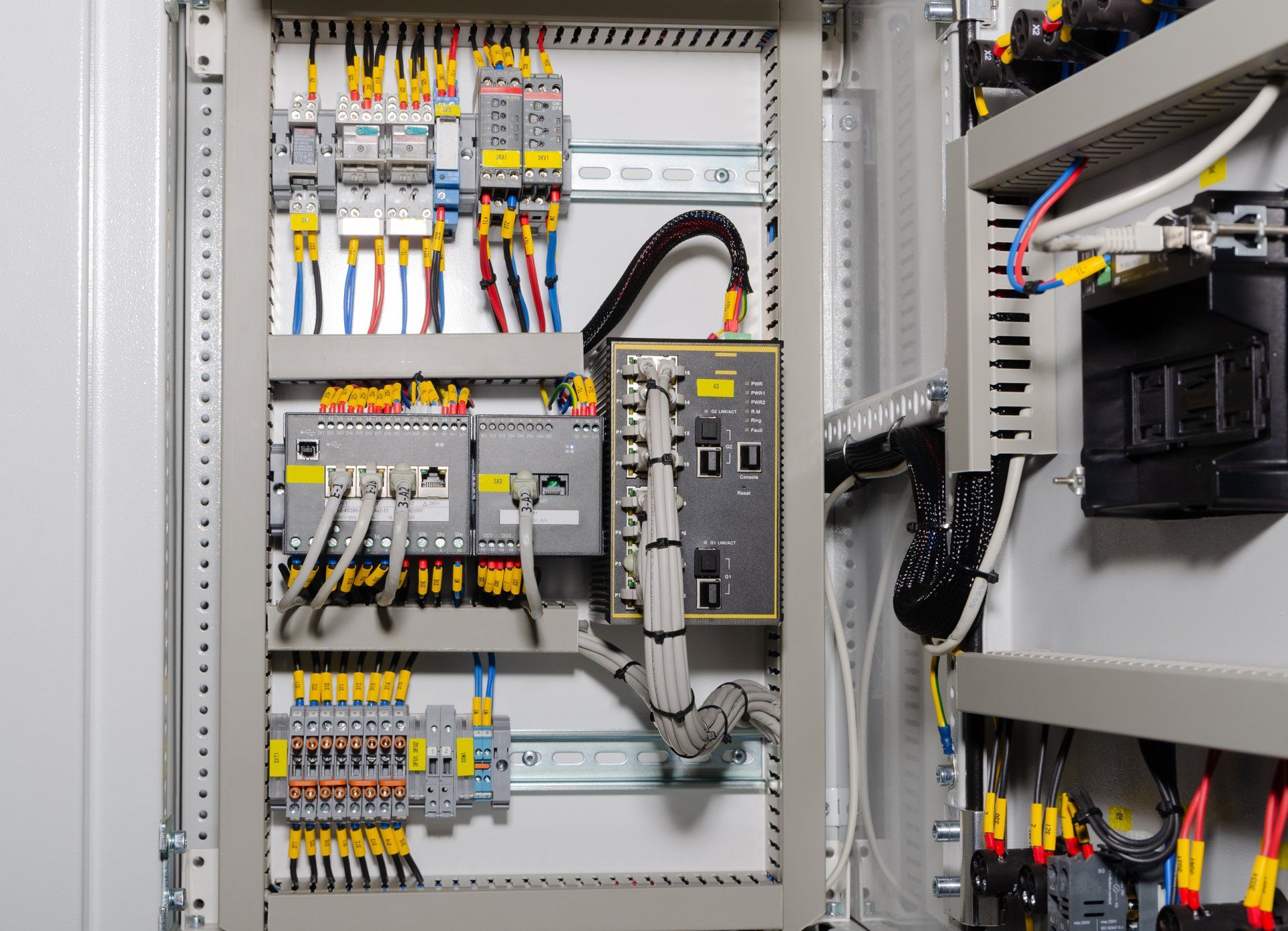

Switchboards

Process control, electro-instrumental or on-board machine control panels

Process control and electro-instrumental interface boards are boards which generally do not involve significant electrical power. They are mainly used to contain the hardware of the control systems, PLCs or DCSs which, with their signal acquisition and measurement peripherals, interface with field instrumentation for the measurement and processing of information on the production process or are used to regulate, even remotely, machine parameters, operating temperatures andswitching lights and air conditioning machines on or off in order to save energy.

In addition to acquisition peripherals, these switchboards also house the interfaces for the field instrumentation, which in the chemical-pharmaceutical sector often represent the EEx (safety) barriers for the field where there is hazardous area equipment.

In these switchboards, there is generally also an electro-pneumatic system where the control valve system is combined with pneumatic drives called solenoid valves. In these sections, there are pneumatic circuits powered and distributed through compressed air-driven devices.

Telesicurezza Service issues the accompanying technical documentation for each supply: single-line and functional wiring diagrams, front and internal topography, terminal boards, equipment list, test certificates and conformity documentation in accordance with current regulations.

Illumination

We convert and build LED lighting systems

LEDs are a real guarantee for lighting efficiency and huge energy savings of more than 80% when compared to conventional lamps.

LED lighting is one of the preferred next-generation solutions in the field of energy-saving lighting.

Thanks to the use of semiconductors, it is the preferred option in a cost-benefit analysis aimed at energy savings and durability. Cold light output allows LED lighting systems great versatility for installation in contact with materials that cannot be heated. Versatility, creativity, sustainability and durability make LED lighting today's solution of the future.

Automatic gates and sectional doors

Automatic gates: installation, certification and maintenance

We specialise in the design, manufacture and servicing of automatic gates and automated security and access control systems.

We are partners with several brands and can provide almost all spare parts.

Telesicurezza Service has an in-house design studio that can create the entire metal construction of the gate with teams of installation and maintenance technicians, a technical assistance and maintenance department and a repair workshop.

Telesicurezza Service puts great emphasis on development and innovation to meet the challenges of an increasingly demanding and competitive market.

Automatic gate and sectional door maintenance

An automatic gate can break and cause greater problems than a traditional gate, although current gates have a long operating life. It may be that the automatic gate does not close properly due to misalignment or incorrect calibration or you may have electric motor or arm problems. An automatic gate that is locked open or locked in the middle of the path are both also foreeseeable problems.

These problems can be avoided with proper maintenance.

Maintenance of the automatic gate is good to do even before the winter. If temperatures drop excessively, the automatic gate can fail to open in cold weather. In all these cases, Telesicurezza Service is available to have the gate serviced or repaired by our gate automation technicians.

Automatic door maintenance

An automated appliance can break and cause greater problems than a normal access door, although automatic doors have an operating life of around 1,000,000 openings. It may be that the automatic door does not close properly due to misalignment or forcing just as it can happen that the automated door stops halfway through the path. These problems can be avoided with proper maintenance performed by specialist technicians.

In all these instances, Telesicurezza Service is available to have your automation serviced or repaired by our experts.

Telesicurezza Service is able to supply and install any automation on windows or doors or to supply the entire window frame including any masonry work necessary for the automated opening system.

Automatic doors

From shopping centres to public places and private homes: where automatic doors can be installed.

This type of closure is ideal in contexts with a high intensity of transit (such as shops, shopping centres, restaurants, hospitals, railway stations, public buildings, etc.) as it allows the flow of people to be controlled and promotes thermal insulation, reducing heat loss in winter and promoting coolness in summer. In commercial establishments, automatic doors are also fitted with anti-panic emergency opening systems that make it possible to manually unlock the door in the event of a fault, power failure or the need to quickly evacuate the environment for safety reasons.

It is also specifically required in places where it is necessary to eliminate architectural barriers and maintain high levels of hygiene, such as hospital wards and operating theatres. In these environments, automatic doors are also fitted with hermetic and semi-hermetic closures because it is important to ensure high levels of thermal, acoustic and sanitary insulation.

Types of automatic doors

Automatic doors are mainly of 3 different types:

Automatic sliding doors

Whether single or double paned, they can be configured in a wide range of variants. They are safe and easy to use and install, they adapt to any entrance and allow simple opening/closing and secure hermetic closure.

Automatic revolving doors

Available with two, three or four sectors, they are ideal when temperature control is of primary concern. They regulate inlet/outlet flows very well, thus ensuring an optimal separation between the internal and external environment.

Automatic swing doors

These automatic doors can be installed on both new installations and existing doors, they can be operated manually and their main feature is to ensure maximum use of the passageway.

As already mentioned, sliding doors are available in a wide range of models and are made of different materials and designs. They offer numerous advantages in terms of functionality and comfort and can be installed in any structural context, even during renovation and on plasterboard walls.

Thinking of giving your entrance a makeover?

Visit us and ask our experts for a consultation!

Sectional doors

Beautiful and well made!

Aprico automatic sectional overhead doors (https://www.aprico.com) installed and sold by Telesicurezza Service are the smartest solution for garages because they improve the aesthetics of the building and offer excellent thermal insulation of the interior. Elegance, comfort, energy saving, mechanical anti-intrusion mechanisms, quality details and finishes are the elements that make Aprico sectional overhead doors the best alternative to traditional and simple overhead sheet metal doors.

New looks, increasingly high quality materials and finishes for garage doors.

And to make access, transit and manoeuvring easier, there are clever and safe opening mechanisms.

Now that anonymous (and sad) garage door closures have been banned for good, doors with an increasingly attractive look are appearing on the street thanks to the elegant contemporary lines and the noble materials of the door panels - mainly wood, available in an infinite range of colours and finishes - new generation doors now perfectly match the other doors and windows of the house, helping to define their style and character. But the surprises go far beyond style. What makes garage owners (and would-be garage owners) even happier is the development of locking system technology: traditional up-and-over doors are giving way to more practical, convenient and secure sectional overhead doors, the intelligent and space-saving alternative.

Electric cabins

MV / LV transformer cabins

In general, the voltage supply from the distributor is the only source of electricity that can support regular operation of an operation, whether it is productive or public, excluding emergency supplies which generally are not able to ensure the regular operation of the whole system. The user's electrical system originates at the delivery point which represents the boundary between the distributor's system and the user's system and from that point the user is responsible. Laws and regulations require electrical systems to be kept efficient with an acceptable level of safety; to fulfil this obligation it is necessary to carry out constant, periodic, scrupulous and adequate preventive and improvement maintenance.

It is appropriate to highlight the need to periodically carry out maintenance of the whole system, with the disconnection of the delivery point, in agreement with the distributor, in order to allow for the maintenance of all the equipment (including that of the distributor) and piping (copper rod or cable lines and relative terminations) connecting it to the user. The total disconnection of the entire system allows the user to operate in complete safety and carry out a complete maintenance operation.

Telesicurezza Service is able to supply different types of transformer substations:

- Open cabin with electrical equipment located in masonry cells with front metal mesh;

- Cabins consisting of medium voltage switchboards with transformers in masonry cells or in metal enclosures;

- Cabins with prefabricated masonry structure;

- Cabins with prefabricated metal structure.

Energy saving

'Energy saving' refers to all activities, measures and technologies aimed at reducing and optimising energy consumption. Energy saving and energy efficiency are essential to reduce the environmental and climate impact of fossil fuels. Consumers who are sensitive to this issue can make use of various solutions, contributing to environmental sustainability and, at the same time, reducing their bills: the effective reduction of electricity and gas consumption through good habits, the transition to the free energy market with the choice of a new operator or the use of technologies that allow the rationalisation of the energy used and self-production with the least possible waste.

Ground systems and protection of atmospheric discharges

What is an atmospheric discharge protection system?

An atmospheric discharge protection system is designed and installed according to precise regulations whose purpose is to reduce the probability of lightning strikes to a structure. In order to know how likely a facility is to be considered self-protected (i.e. it does not require an atmospheric discharge protection system), a detailed study by a qualified technician according to certain European technical regulations is required. This report is a compulsory document to be carried out by all employers for their operation.

If the technical report reveals the need for an atmospheric discharge protection system, it must be designed and installed by professionals registered with technical orders and registers.

Atmospheric discharge protection systems include rod-type systems, such as the typical lightning rod, rope-type systems and cage-type systems.

Therefore, if an activity has an atmospheric discharge protection system, it must be periodically checked by an inspection body or by ASL and ARPA.

This system must then be checked by an inspection body periodically to check its condition and that all maintenance has been carried out regularly. This check is required by Presidential Decree 462.

Home automation

What is home automation

Home automation includes all those processes that deal with the study of technologies to improve the quality of life in homes and buildings. But it does not stop there, as home automation can increase the performance and functionality of the various systems that make up a home.

This is done by optimising consumption and providing access to various functions such as security, energy saving, control, communication and comfort.

While a traditional system can be controlled by activating normal commands, such as a switch, which are incapable of communicating with each other, the home automation system allows the various functions to be governed from a single control point, guaranteeing coordinated management of the various smart devices in the home.

Networks and structured cabling

Structured cabling networks - LANs

The need to connect and interconnect more and more computer devices through the Internet or with dedicated LANs, makes it necessary to create data networks with high speed, reliability, flexibility and scalability.

In buildings, whether civil or industrial, cabling that respects this is not just an interconnection system but a strategic element, sharing the resources of the company, employees and customers and projecting the factory computer system as the fulcrum of the company itself.

In a data transmission system, the nerve centre is the structured cabling

system made up of a set of copper or fibre optic cables, active and passive equipment (bridges, routers, switches) that are suitably wired and interconnected to allow connectivity between the various components of the company network represented by the end users (computers, smartphones, tablets, etc.).

The heart of the structured cabling system is the star centre, represented by a rack cabinet in which all the signal management devices (bridges, routers, switches, etc...) and connection to the external data and telephone network (HDSL modem, switchboard) are grouped. The electrical connection to the sockets intended for the end users is developed from the star cabinet.

The network architecture must be suitable for providing adequate transmission support for communications within the company premises, in compliance with the reference standards. The cabling must be realised in full compliance with the standards and regulations in order to obtain a high degree of reliability, security and functionality, as well as to allow a high level of diagnostic support.

Air conditioning systems

Comfort, consumption, coordination: three requirements that must meet the construction of air conditioning systems for work environments, be they companies, offices and banks.

Comfort for the user: each office or work area must be able to have independent temperature regulation, adequate air exchange and correct humidity.

Consumption: must be contained for the company and are obtained through the careful design of air conditioning systems.

Spatial and temporal coordination: the position of the equipment, anemostats, fan coils is performed according to the layout of the office or bank furniture. The coordination of our technicians guarantees the correct succession of all the various processes within the construction site.

In addition to the design of the set-up and furnishings, Telesicurezza Service carries out the design and construction of air conditioning systems optimized for the specific site, offering functional solutions characterized by an excellent quality-cost ratio.

In the field of air conditioning and air conditioning, our company offers its customers a wide range of products and customized solutions for civil and industrial systems throughout Italy.

Telesicurezza Service offers an assistance service for all systems of any type and size.

Types of climate control systems that Telesicurezza Service offers:

· Heating and cooling systems using heat pump equipment;

· Ducted primary air exchange systems using heat recovery units or AHUs (air handling units, especially used for office and bank spaces);

· Heating systems with district heating units;

Centralisation to switch off the systems remotely, check correct operation or adjust temperatures.

Heating systems

Heating system installation

Telesicurezza Service designs, installs and maintains heating systems taking into account various factors and various variables, because an adequate design will have a positive effect on the economic, aesthetic, ecological aspect, as well as on the method and efficiency of heat propagation.

There is no better heating system than another in absolute terms but individual circumstances and requirements of the installation site can inform the choice in equipment.

Below, we cover different types of heating, among which you will definitely be able to find the one that best suits you and your needs.

System with radiators or heaters

Now present in most homes, the traditional heating system is far from extinct as it remains a suitable and "convenient" solution in many situations.

Baseboard heating

The skirting board heating system is an innovative system of constant and homogeneous heat propagation for heating any type of room.

Baseboard heating: water and electric variants

The water version can be operated with any heat generator (gas or oil boiler, heat pumps, etc.) but also with renewable sources, whose heat is released from the skirting board heating to the walls.

Wall heating system

A variant of the underfloor system is wall heating. As with skirting board heating, it is based on the same principle of propagating heat by radiating it onto the wall and releasing it to the room.

Floor systems

Underfloor heating

This type of heating system can be either closed-circuit water heating, i.e. consisting of pipes, or electric heating, i.e. consisting of electrical resistance.

District heating system

A district heating system is a district heating system that uses a series of pipelines in a network and transports heat from a power station to individual units.

Heating system with natural gas or LPG boiler

Speaking of costs:benefit ratios, it is very important to consider the type of power supply when choosing a heating system.

Convector heating

Usually used as a supplement to other heating systems to speed up the spread of heat or to increase its intensity in very cold environments, convectors certainly play a major role in the speed and uniformity of heat diffusion.

Water systems

Water-sanitary systems: supply and drainage networks

Telesicurezza Service operates in the civil and industrial sectors with competence and professionalism, guaranteeing continuous technological innovation of its materials. The company, which is constantly expanding, offers a wide range of services and solutions.

Turning on the tap in your own home and having access to drinking water, including hot water if necessary, is possible thanks to an essential system for modern homes: the water-sanitary system.

Water systems allow a constant supply of drinking water, so it is essential to pay due attention to the quality of water intended for human consumption, considering that it can be altered by external agents such as chemical and microbiological factors.

Preserving good water quality must be the main objective of those designing, installing, operating and maintaining water distribution networks. Some simple preventive measures can be the selection of pipe materials, correct sizing of the system (actual calculation of actual pressure losses) and maintaining hot water temperatures above 50°C.

Water systems

A sanitary water system includes

- an adduction or supply system, consisting of all the networks, components and equipment that allow the adduction and distribution of hot and cold water to the various users of a building;

- a drainage system, which allows the disposal of the quantities necessary to meet the needs of the users.

Adduction networks

A water supply system starts at the point of connection to the public drinking water supply and ends at the point where the water is used, i.e. the sanitary appliance (tap, bath, bidet, etc.).

The supply systems in almost all homes are connected directly to the public water supply network.

Tanks and autoclave systems

When the pressure is not sufficient to reach the highest floors of a building, auxiliary lifting systems must be installed, such as the autoclave - a hermetically sealed metal tank containing a compressor that pumps air into the tank to prevent pressure variations and allow the system to operate at full capacity.

Pipes and special components for water networks

The distribution network generally consists of horizontal distribution pipes, vertical risers, distribution pipes to the floors and to the various appliances, and shut-off devices (valves).

Water meters and counters

Drinking water distributed by water systems, although complying with the specific values set by law, may nevertheless contain a number of substances (e.g. encrusting salts) that can cause serious damage both to distribution networks and to the appliances that use the water. It is therefore possible to treat the water before it is distributed in order to reduce the presence of undesirable substances.

Regulations

As with other types of systems, the installation of the water system is governed by very precise regulations that make it compulsory to comply with certain construction standards, whether for a completely new home or one undergoing renovation.

Air treatment plants

Air Handling Units

The air handling unit, better known by its acronym U.T.A. (air handling unit), is equipment for treating air in closed environments. It is usually made up of a heat exchange coil with chilled water (so evaporation takes place in the evaporator of the refrigerating machine) and hot water, both for cooling and heating, or a direct expansion coil in which the refrigerant gas circulates, for which evaporation takes place in the coil itself inside the rooms where it is used, an air filter and a low head intake/outlet fan.

For large air-conditioning systems, the definition of central air handling units, or A.T.C., is adopted. (air handling centres), whether they are all external air or mixed air. Their purpose is to take the air and treat it according to thermo-hygrometric requirements. The parameters involved in air treatment are temperature, humidity, velocity and purity. For each of these parameters there is a component of the machine capable of controlling, regulating and/or modifying it.